VAL6 VS LEADING ONLINE HEATER

Why Val6 Infrared

VAL6 is an original industrial infrared heater line with decades of manufacturing experience, and this page clarifies how its radiant technology compares to the other leading brands and traditional forced-air heaters. Infrared radiant heat warms people and surfaces directly rather than relying on hot air, which is central to performance in semi-open and drafty environments.

How to measure performance

- Usable heat: Measure how effectively the heater warms people, objects, and work surfaces through radiant transfer rather than just raising air temperature.

- Heat loss: Consider losses to convection, ventilation, and wind; radiant heat is less affected because it targets surfaces directly.

- Fuel-to-heat conversion: Look for combustion and chamber designs that deliver near-complete conversion with clean, odorless operation.

- Coverage and control: Prioritize uniform radiant output, disk size, and high/low control to match changing conditions and minimize waste.

Indoor air and comfort

VAL6 generates infrared heat without air movement, reducing dust circulation and helping maintain a cleaner-feeling workspace. Its combustion design supports clean, odorless, smokeless operation, which is beneficial for personnel comfort and nearby processes. Radiant heat also minimizes the need to overheat entire air volumes just to keep people warm at the work surface.

Semi‑open and outdoor performance

VAL6’s radiant output is not affected by wind like forced-air units, enabling targeted warmth for bays, loading docks, open-sided shops, and construction zones. Because the heat is absorbed by people and surfaces, it remains effective in conditions that quickly strip away heated air from conventional blowers. This makes radiant a strong choice for jobs that require doors open or frequent ventilation.

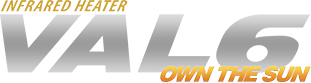

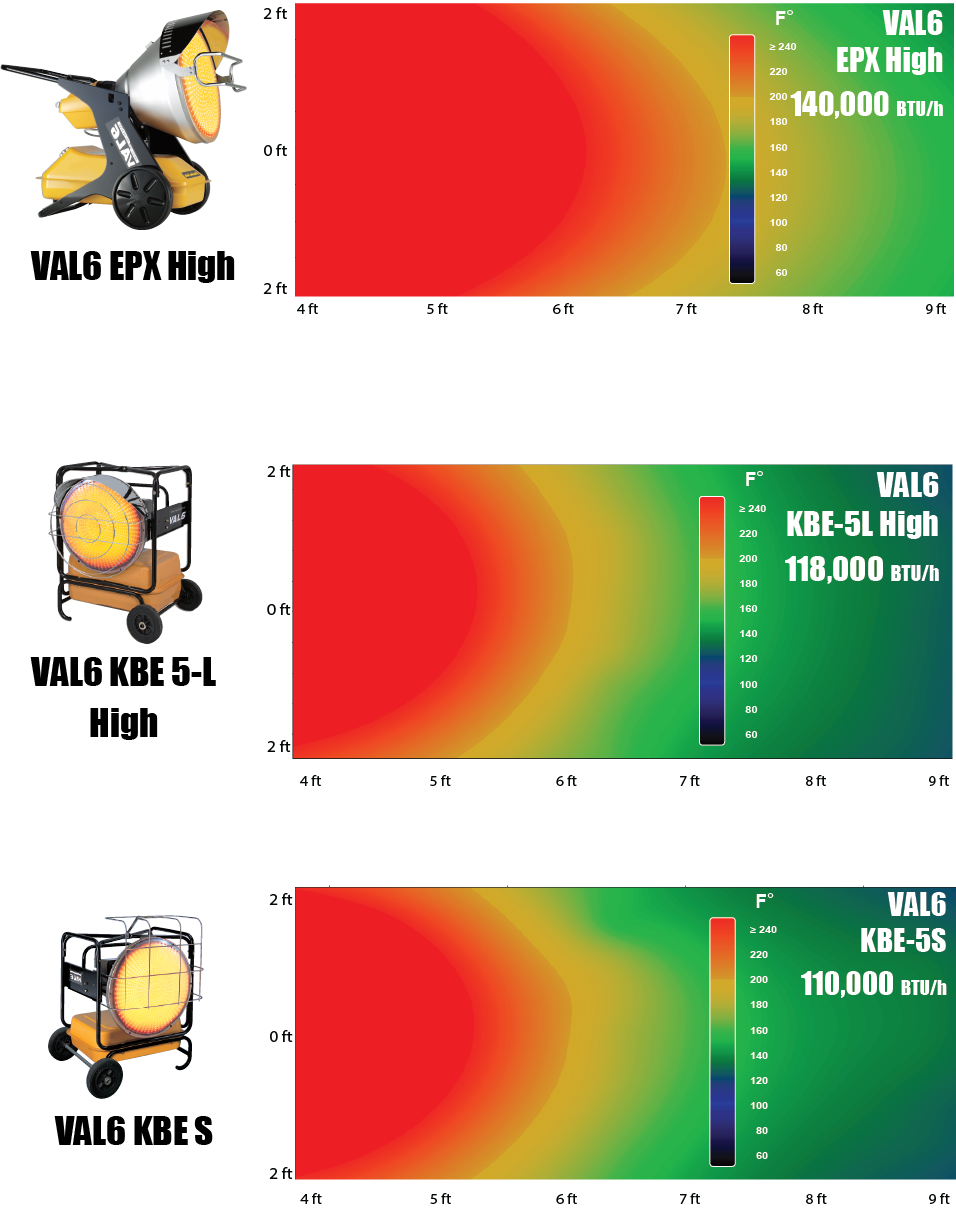

COMPARING ACTUAL INFRARED HEAT OUTPUT OF VAL6 TO LEADING ONLINE COMPETITOR

Infrared Conversion Ratio (ICR) – Perhaps the most important measure of infrared heater performance is how efficiently a unit converts energy into infrared heat. (Please refer to the chart on page 20.) The largest model from our largest Leading Online competitor has the lowest infrared conversion ratio, highlighting that high BTU does not guarantee better heating performance.

VAL6 VS THE LEADING ONLINE INFRARED HEATER IN HEAT DISPERSION

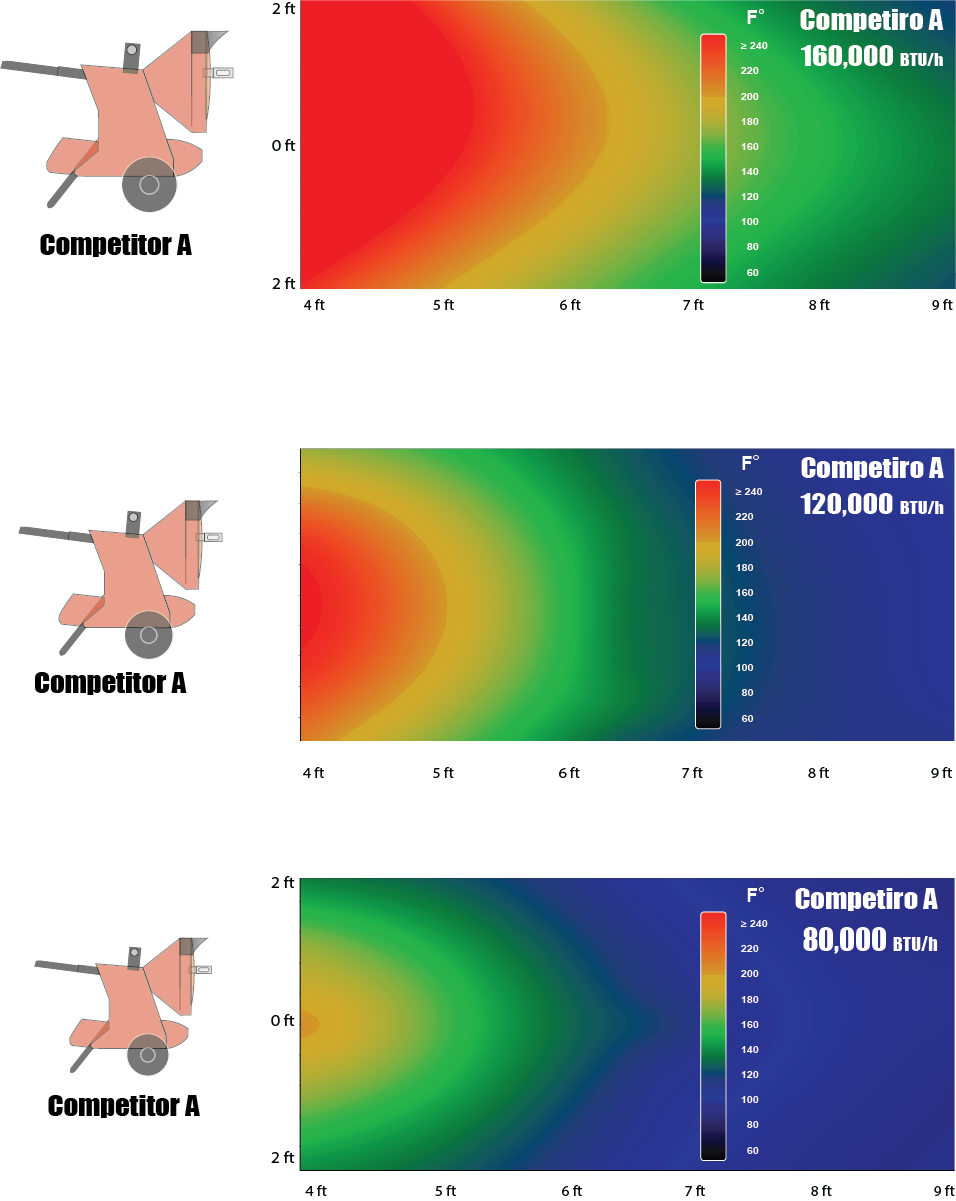

COMPARING HOW A LARGER HEATING DISK PROVIDES GREATER HEAT DISPERSION

Disk size matters – While the competitor's largest model looks visually large, its disk area is only about 69% of the EPX, while the KBE5L is about 81%, and the second largest model of the competitor is 58% of the EPX. The reason for this, is Leading Online Infrared Heater combustion chamber’s diameter is smaller than its disk, producing less heat output.

VAL6 INFRARED HEATER TECHNOLOGY VS TRADITIONAL CONVECTION HEATER

Radiant vs Convection / Forced Air Heating Technology

Infrared radiant heat targets people and objects directly, so comfort arrives faster and is less impacted by moving air. Forced-air systems heat air first, which can escape through drafts, vents, or open doors before it benefits people on the jobsite. In semi-open or windy areas, radiant heaters maintain warmth where it’s needed, while convective systems suffer from pronounced heat loss.

Efficiency and fuel use

VAL6 emphasizes a combustion chamber that enables virtually complete fuel-to-energy conversion, translating to strong usable heat per gallon. Model-level specs make fuel planning straightforward.

Design details that matter

The EPX is built around an enlarged combustion chamber, improved atomization, and a radiation disk that’s 20% larger for wider, farther-reaching infrared coverage. High/low output control and long run times (about 15 hours high, 20 hours low per tank on EPX) provide flexibility across changing conditions without frequent refueling. These details translate to more usable radiant heat, better area coverage, and reduced waste from convective losses.